Factory Tolerance Restoration (FTR) is a critical process for precision manufacturing of high-end vehicles like Mercedes-Benz, focusing on calibrating ADAS components for maximum accuracy and safety. This revolutionary approach enhances vehicle performance by ensuring seamless integration of technologies like autonomous driving and collision avoidance systems. Through meticulous restoration to OEM specifications, FTR guarantees original equipment quality, protecting drivers and passengers with enhanced structural integrity and reliable safety features.

Factory Tolerance Restoration (FTR) is revolutionizing automotive manufacturing, particularly for Advanced Driver Assistance Systems (ADAS) and safety-critical components. By meticulously controlling and minimizing dimensional variations during production, FTR ensures the precise assembly of sensors, cameras, and actuators required for ADAS functionality. This innovative approach enhances system reliability, improves safety margins, and paves the way for more sophisticated driver assistance features. In this article, we explore the foundational principles of FTR, its pivotal role in ADAS advancement, and strategic implementation guidelines for automotive manufacturers.

- Understanding Factory Tolerance Restoration: The Foundation for Precision Manufacturing

- Enhancing ADAS and Safety Systems: How FTR Plays a Vital Role

- Benefits and Implementation Strategies for Factory Tolerance Restoration in Automotive Manufacturing

Understanding Factory Tolerance Restoration: The Foundation for Precision Manufacturing

Factory Tolerance Restoration is a meticulous process that forms the cornerstone of precision manufacturing. It involves meticulously calibrating and adjusting components within a vehicle’s ADAS (Advanced Driver Assistance Systems) and safety systems to achieve maximum accuracy. By restoring factory tolerances, car body shops ensure that every part functions in harmony, allowing for seamless integration of cutting-edge technologies like autonomous driving features, collision avoidance systems, and advanced airbag deployment mechanisms.

This meticulous approach is particularly crucial in high-end vehicles, such as those produced by Mercedes-Benz, where precision engineering and safety are paramount. A well-executed factory tolerance restoration not only enhances the overall performance of these sophisticated systems but also plays a vital role in maintaining the vehicle’s structural integrity. It’s a critical service offered by top-tier body shops, ensuring that your car is not just repaired but restored to its original specifications, thereby safeguarding both drivers and passengers on the road.

Enhancing ADAS and Safety Systems: How FTR Plays a Vital Role

Factory Tolerance Restoration (FTR) is a critical process that enhances the performance and reliability of Advanced Driver-Assistance Systems (ADAS) and safety mechanisms in vehicles. By accurately restoring the factory tolerances, auto collision centers can ensure that these systems function optimally, thereby improving overall vehicle safety. This meticulous process involves the precise adjustment and calibration of various components, ensuring they meet the original equipment manufacturer’s (OEM) specifications.

When a vehicle undergoes a collision or repair at a collision repair center, even minor disruptions to its initial factory settings can impact the effectiveness of ADAS sensors and safety systems. FTR counteracts this by reestablishing the critical tolerances required for these systems to work in harmony. This meticulous restoration guarantees that features like adaptive cruise control, lane-keeping assist, automatic emergency braking, and other active safety mechanisms function as intended, ultimately contributing to a safer driving experience.

Benefits and Implementation Strategies for Factory Tolerance Restoration in Automotive Manufacturing

Factory Tolerance Restoration (FTR) is a game-changing strategy in automotive manufacturing, offering significant benefits for Advanced Driver Assistance Systems (ADAS) and overall vehicle safety. By implementing precise and controlled tolerances during the manufacturing process, FTR ensures that critical components align perfectly, enhancing the performance and reliability of ADAS sensors and cameras. This meticulous approach minimizes light interference, reduces false readings, and improves overall system accuracy.

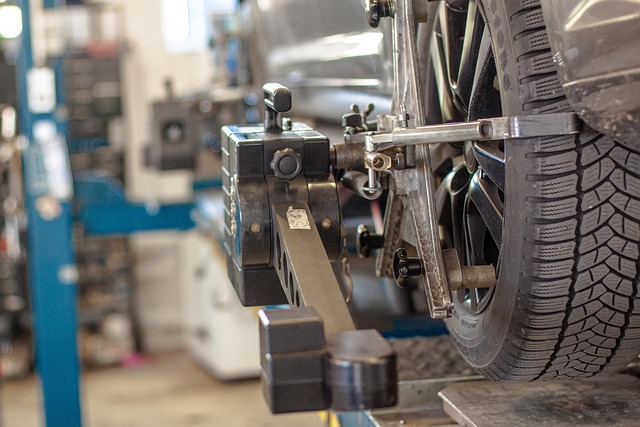

The successful integration of FTR requires a strategic implementation plan. Car paint services and collision repair facilities play a vital role by ensuring vehicles are restored to their pre-accident condition with accurate dimensions and specifications. This involves advanced dent removal techniques and meticulous body repairs, followed by precise alignment and calibration of ADAS components. By adopting these strategies, manufacturers can achieve the required tolerances, leading to safer, more reliable vehicles equipped with cutting-edge safety systems.

Factory Tolerance Restoration (FTR) is a pivotal strategy in modern automotive manufacturing, enhancing the precision and reliability of Advanced Driver Assistance Systems (ADAS) and safety mechanisms. By meticulously controlling and restoring tolerances at the factory level, manufacturers can ensure consistent performance and robustness of these critical systems. This not only improves overall vehicle safety but also paves the way for more sophisticated autonomous driving capabilities in the future. Implementing FTR as a standard practice is thus a game-changer in the industry, fostering innovation while maintaining stringent safety standards.